Starting a business is a thrilling experience, but it usually entails heavy financial burdens. Whereas some businesses are able to start on a tight budget, others—especially those involving specialized facilities such as warehouses—require a bigger initial investment.

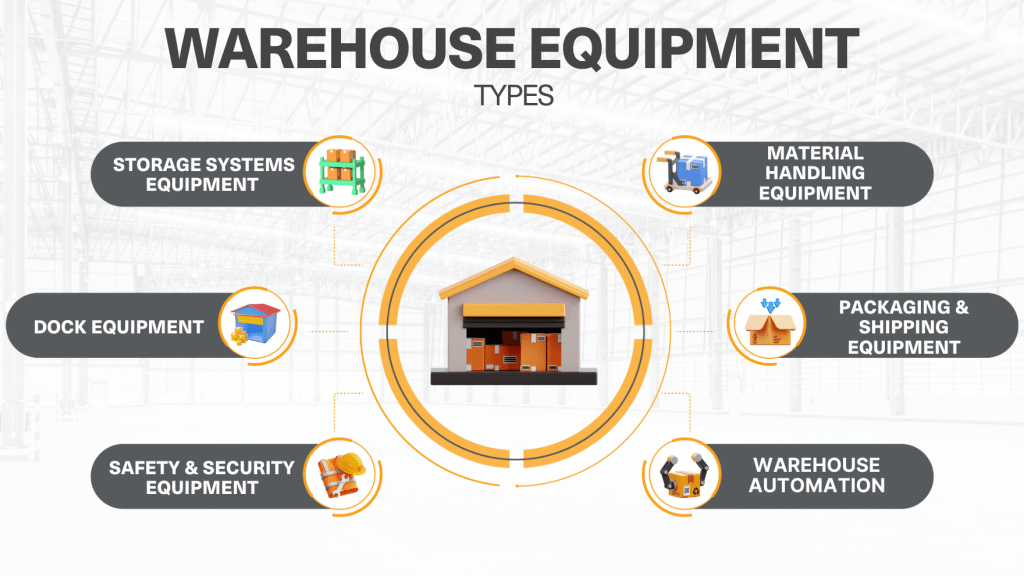

If you are looking to start a warehouse for inventory storage, assembly, or other uses, the expenses add up fast. From shelving and equipment to forklifts and equipment, the initial costs are overwhelming. But you can begin building your business without breaking the bank if you prepare and make the right decisions. Here is how.

Invest in Your Knowledge Before Your Business

Before you even spend money on purchasing equipment or renting a warehouse, invest time in learning. As a business owner, the more you master making smart money choices, the better your business will do. The internet offers plenty of resources with which to start your education: online courses, webinars, and even full-fledged master’s degrees like a master’s in management. These resources can show you how to build budgets, balance cash flow, and save money that is particular to your niche.

Through proper education with information, you can be better at spotting wasteful spending, and you can get better deals in negotiations, along with making better financial choices. The more money you spend on yourself, the greater your success will be at creating a business that is viable and profitable.

Use Consignment or Used Equipment

One of the most cost-effective ways to save money in equipping a warehouse is the purchase of second-hand or consignment equipment. Most companies sell their warehouse materials, shelving, forklifts, and other machinery at prices that are much lower than their original cost. It typically happens when companies downsize operations, outsource operations, or close shop.

By procuring high-quality, used items, you can drive down your initial costs dramatically without sacrificing functionality. Online marketplaces like eBay and specialty industrial marketplaces are all great starting points. Going further, networking with other entrepreneurs within your field can also provide the possibility to buy second-hand equipment straight from them.

Investigate Financing Options

Using all your available capital to set up your warehouse can be risky. It is essential to preserve some funds for ongoing expenses like inventory, payroll, and utilities, especially since it may take months or even years for your business to become profitable. Instead of depleting your savings, consider applying for a business loan to cover the cost of equipment and supplies.

There are several financing options available, including:

- Traditional Business Loans: These offer a sum of money that you pay back in the future with interest.

- Business Credit Cards: Good for smaller, ongoing expenses, business credit cards usually include rewards or cashback rewards.

- Equipment Financing: Primarily for buying equipment, these loans collateralize the equipment itself, which usually means lower interest.

Prior to taking out a loan, shop around for interest rates, terms, and repayment periods to determine the best choice for your financial needs.

Prioritize Necessary Purchases

It is tempting when establishing a warehouse to go out and buy the most advanced technology or the best equipment available. But not everything is a necessity right out of the gate. Begin by determining the absolute necessities—such as shelving, fundamental machinery, and safety gear—and prioritize those first.

For instance, if you cannot afford a brand-new forklift, rent one or buy a trusted used one. Likewise, rather than shelling out money for costly software in the beginning, look for low-cost or no-cost alternatives that can suffice your current requirements. Once your business expands and you start earning revenues, you can invest in upgrades and expansion.

Tap into Networking and Partnerships

Establishing connections with other companies and industry players can provide opportunities for cost reduction. For example, you can collaborate with the business next door to share storage space or machinery, lowering your overhead expenses. Networking can also generate referrals for cheap suppliers, contractors, or service providers.

Also, think about becoming a member of industry associations or online communities where members exchange tips, resources, and even equipment. Working together with others in your industry can help you do more with less.

Use Lean Operations

Using a lean strategy in your warehouse operations can save you money while optimizing efficiency. Begin by streamlining your layout to reduce wasted space and eliminate the need for unnecessary shelving or equipment. Utilize inventory management software to monitor stock levels and prevent overordering, which ties up capital in unsold inventory.

Educate your staff on best practices for efficiency and safety, minimizing the risk of expensive accidents or mistakes. By simplifying your operations from the very beginning, you can reduce your recurring costs and enhance your bottom line.

Outsource When Necessary

If the expense of hiring a full-time staff or buying specialized equipment is out of your budget, you might want to look into outsourcing. For instance, you might outsource shipping and inventory management to a third-party logistics company, cutting back on the need for a huge in-house staff. By outsourcing, you only pay for the services you require, when you require them, leaving capital available for other things.

Final Thoughts

Starting a business, particularly one that necessitates a warehouse, does not need to empty your wallet. Investing in your education, buying used equipment, considering available financing, and making necessary investments first can get an operational and effective business established without breaking the bank.

With proper planning and sound decision-making, you can lay the foundation for your business while maintaining the financial pillars. The key is not only to launch your business but to create a viable and profitable business that can succeed in the long term.